Top 10 Best Robotic Welding Cobots this 2025

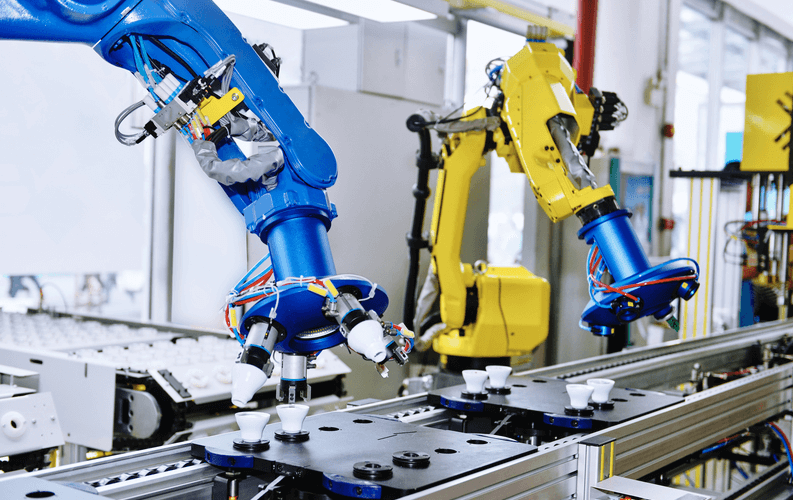

The demand for advanced automation in manufacturing is higher than ever, and robotic welding cobots are emerging as one of the most effective solutions. These collaborative robots combine the accuracy and consistency of robotic welding with the flexibility to work safely alongside human operators. The 2025 cobot models feature easier programming, quicker setup, and better safety, and this guide lists the top 10 options to help you choose the right one for your needs.

What Is Robotic Welding?

Robotic welding performs tasks faster, more accurately, and with less waste. Modern robotic arms, such as PUMA and UR types, are designed to fit different workspaces, prevent collisions, and even replicate the techniques of skilled welders. By combining human expertise with robotic precision, these systems enhance both manufacturing efficiency and weld quality.

Key Features to Consider When Choosing a Robotic Welding Cobot

When selecting a robotic welding cobot, look for these essential features:

- Built-in Vision System – Integrated cameras for object recognition, positioning, and quick recalibration without external equipment.

- Easy Programming – User-friendly, drag-and-drop software that eliminates the need for advanced coding skills and allows workflow reuse.

- Safety & Collaboration – Collision detection, force-limiting technology, and compliance with international safety standards to work safely alongside humans.

- Welding-Specific Tools – Functions tailored for MIG, MAG, and TIG welding, including current and speed control, plus flexibility for different production setups.

- Performance & Precision – High speed, accuracy, and suitable payload and reach options to match production needs.

- AI & Advanced Integration – Smart vision, AI-powered tools, and accessories that enhance adaptability, debugging, and efficiency.

These features ensure the cobot is safe, flexible, precise, and efficient, making it a strong fit for modern welding applications.

See also: The Impact of Silver Price Fintechzoom: Comprehensive Analysis

Top 10 Best Robotic Welding Cobots in 2025

Top 1: TM Robot

The Techman Robot is an affordable collaborative robot. It has a built-in camera system and simple drag-and-drop programming, making it easy to use and suitable for many tasks.

- Pros: Built-in vision system, affordable, and fast to set up.

- Cons: Can carry only light loads and has a smaller global support network.

Ideal For: SMEs needing economical, fast-to-deploy solutions with vision capabilities, e.g., quality inspection alongside welding.

Top 2: ABB Robotics (GoFa Welding Cobot)

No-code programming, “Weld Easy”/“Weld Faster” modes, industrial-grade precision.

- Pros: Extremely user-friendly, rapid programming, consistently high weld quality.

- Cons: Higher investment and control requirements.

Ideal For: Production environments seeking quick, easy deployment with minimal programming expertise and high welding efficiency.

Top 3: Universal Robots (UR)

Reliable in tough conditions, user-friendly, and equipped with safety controls.

- Pros: Reliable, user-friendly, safe, and supported globally with a strong ecosystem.

- Cons: Payload and reach may be limited for heavy-duty tasks.

Ideal For: Best for medium-sized businesses needing safe and flexible cobots with reliable support.

Top 4: KUKA Robotics

Supports MIG, TIG, and laser welding; high precision and repeatability; drag-and-drop setup with preconfigured profiles.

- Pros: Flexible automation, high compatibility with welding sources, enhanced safety for human collaboration.

- Cons: High upfront investment; programming can be complex for beginners.

Ideal Applications: Automotive manufacturing, battery production (EVs), and the aerospace industry.

Top 5: FANUC Robotics

User-friendly programming (ARC Tool Software), compact design, suitable for high-mix, low-volume production.

- Pros: Versatile, safe for human interaction, backed by a global support network.

- Cons: Limited payload; potentially higher operating costs.

Ideal Applications: SMEs, educational institutions, and small manufacturers needing adaptable welding automation.

Top 6: Kawasaki Robotics

High payload capacity (up to 1500 kg), modular design, open architecture for integration with various welding technologies.

- Pros: Heavy-duty performance, customizable, durable for industrial environments.

- Cons: Complex integration; higher cost.

Ideal Applications: Heavy industry (shipbuilding, construction), automotive large assemblies, aerospace requiring precision and payload.

Top 7: Boston Dynamics

Highly mobile quadruped robot (Spot), autonomous operation with advanced sensors and AI, integrates with centralized software.

- Pros: Operates in difficult or hazardous environments, capable of detailed data collection, and safe for dynamic surroundings.

- Cons: Not specialized for welding, high cost, and limited payload capacity.

Ideal Applications: Infrastructure inspection, hazardous or hard-to-reach environments, data collection missions.

Top 8: Standard Bots (RO1 Cobot)

Affordable, built-in AI vision, no-code drag-and-drop programming, safety sensors for human collaboration.

- Pros: Cost-effective, easy to use, versatile for welding, palletizing, and inspection.

- Cons: Low payload and fewer advanced features.

Ideal For: Small to medium-sized enterprises, educational institutions, and prototype development.

Top 9: Kinova Robotics (Gen3)

Lightweight, compact, advanced 2D/3D vision integration, embedded controller for streamlined operation.

- Pros: High precision, adaptable for various tasks, robust performance.

- Cons: Slower speed for high-volume tasks, limited torque control in ROS.

Ideal For: Medical robotics, R&D, and service robotics requiring precise control and human collaboration.

Top 10: Komau Robotics

Modular design (positioners/tracks), high payload capacity, open architecture for custom integration.

- Pros: Heavy-duty performance, highly customizable, durable for industrial use.

- Cons: Complex integration and higher cost.

Ideal For: For heavy industry, large automotive assemblies, and precise high-payload aerospace work.

Benefits of Using Robotic Welding Cobots

- Enhanced Productivity and Efficiency

Robotic welding cobots increase productivity by working continuously, meeting high production demands, and maintaining consistent output.

- Consistent, High-Quality Welds

Cobots deliver precise, repeatable welds, minimizing variations and defects. Their consistency reduces rework and scrap, resulting in significant cost savings.

- Improved Worker Safety

Cobots make work safer by doing dangerous and repetitive welding tasks, keeping workers away from heat, fumes, and possible injuries.

- Cost-Effective Automation

Collaborative robots are generally more affordable and easier to implement than traditional industrial robots. Their intuitive programming interfaces and compact design make them accessible for small to medium-sized enterprises, providing a faster return on investment.

- Flexibility and Adaptability

Cobots can be quickly reprogrammed and redeployed for different tasks, making them ideal for high-mix, low-volume production environments. This flexibility allows manufacturers to respond rapidly to changing production requirements.

- Addressing Skilled Labor Shortages

Cobots handle basic welding tasks, allowing skilled welders to focus on more complex work.

- Ease of Integration

The compact design and user-friendly interfaces of cobots make it easy to integrate them into existing production lines without major modifications. This reduces downtime and accelerates the automation process.

Robotic welding cobots provide productivity, quality, safety, and flexibility, making them a cost-effective and adaptable solution for competitive manufacturing.

Challenges and Considerations for Robotic Welding Cobots

- Initial Investment and Payback Period

Robotic welding cobots require an upfront investment that includes the system cost, setup, and ongoing maintenance. Typically, the return on investment (ROI) ranges from 18 to 24 months. After this period, the system continues to deliver cost savings, making it a worthwhile long-term investment for fabrication and manufacturing companies.

- Limitations in Heavy-Duty or High-Volume Production

Cobots are most effective for small to medium production runs and tasks that require flexibility. They are slower and less efficient than traditional industrial robots for heavy-duty or high-volume operations, such as large assembly lines producing identical parts. However, cobots excel in environments that need quick adjustments and adaptability.

- Training Requirements for Operators

Operators must be trained in safety, programming, troubleshooting, and maintenance to use cobots efficiently. Practicing hands-on is important to stay safe, work more efficiently, and avoid mistakes or accidents.

- Maintenance, Software Updates, and Technical Support

Regular maintenance keeps cobots functioning optimally. This includes inspections, preventative maintenance, lubrication, and replacement of consumables. Staying updated with software and programming improvements is also important for efficiency and minimizing downtime. Manufacturers often provide portals for software updates, technical support, and troubleshooting resources to help operators maintain peak performance.